THE BESSEMER PROCESS

These incredible photos capture the power of the Bessemer process. Sir Henry Bessemer developed the Bessemer process in the 1850s. In this method, molten pig iron is introduced into a large, pear-shaped vessel called a converter. Air is then blown through the molten iron to oxidize impurities, particularly excess carbon. The oxidation process raises the temperature of the molten metal, eliminating impurities and resulting in the production of steel.

View fullsize

![Black and white photo of a bessemer converter during operation with workers standing around]()

Black and white photo of a bessemer converter during operation with workers standing around

View fullsize

![Balck and white photo of a bessemer in operation with sparks from the melted steel]()

Balck and white photo of a bessemer in operation with sparks from the melted steel

View fullsize

![Black and white photo of the steelmaking plant furnace]()

Black and white photo of the steelmaking plant furnace

View fullsize

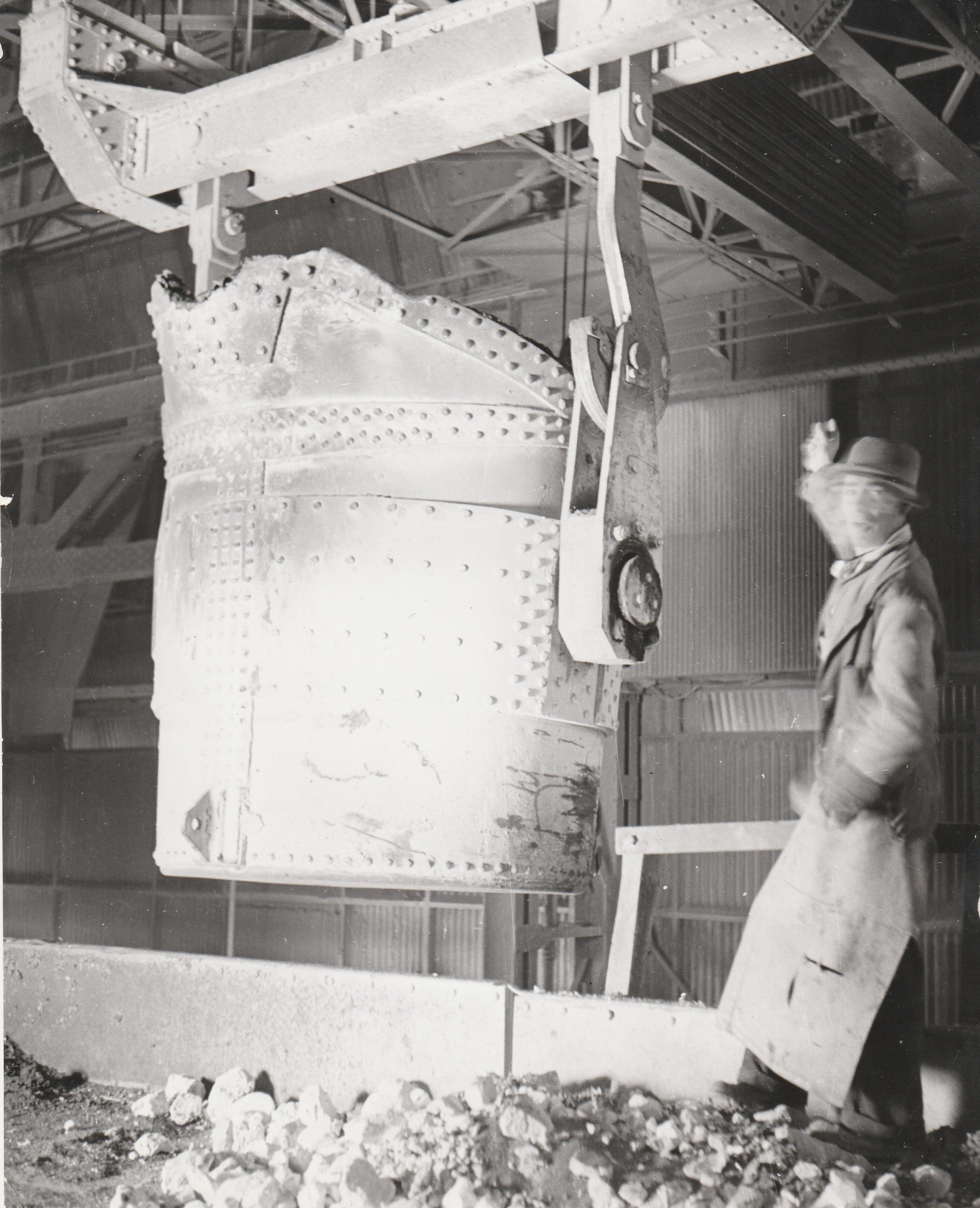

![Black and white photo of a ladle]()

Black and white photo of a ladle

View fullsize

![Black and white photo of a bessemer]()

Black and white photo of a bessemer

View fullsize

![Black and white photo of a ladle pouring molten steel into a furnace]()

Black and white photo of a ladle pouring molten steel into a furnace

View fullsize

![Black and white photo of a bessemer converter pouring melted steel into a ladle]()

Black and white photo of a bessemer converter pouring melted steel into a ladle

View fullsize

![Black and white photo of a bessemer converter pouring melted steel into a ladle]()

Black and white photo of a bessemer converter pouring melted steel into a ladle

View fullsize

![Black and white photo of the inside of the steel factory]()

Black and white photo of the inside of the steel factory

View fullsize

![Black and white photo of a bessemer converter with light sparks from the melted steel]()

Black and white photo of a bessemer converter with light sparks from the melted steel

View fullsize

![Black and white photo of a bessemer converter in operation]()

Black and white photo of a bessemer converter in operation

View fullsize

![Black and white photo of a bessemer converter in operation]()

Black and white photo of a bessemer converter in operation

View fullsize

![Black and white photo of a bessemer converter in operation]()

Black and white photo of a bessemer converter in operation

View fullsize

![Black and white photo of molten pig iron running down in channels]()

Black and white photo of molten pig iron running down in channels

View fullsize

![Corby works]()

Corby works

View fullsize

![Black and white photo of a bessemer converter in operation with a worker standing in front of it]()

Black and white photo of a bessemer converter in operation with a worker standing in front of it

View fullsize

![Black and white photo of a row of active converters in plant area]()

Black and white photo of a row of active converters in plant area

Go to Basic Oxygen Steelmaking (B.O.S) Images